If you’ve thought about using closed cell foam for your next project, you should learn everything you can about the material, so you can make the best decision.

While open cell foam is valued for its absorption and flexibility, closed cell foam is noteworthy for its strength and water-resistance.

It all depends on what you’re using the foam for and what you want the outcome to be.

Here is a deep dive into the definition of closed cell foam, the best times to use it, and instances where you should avoid it.

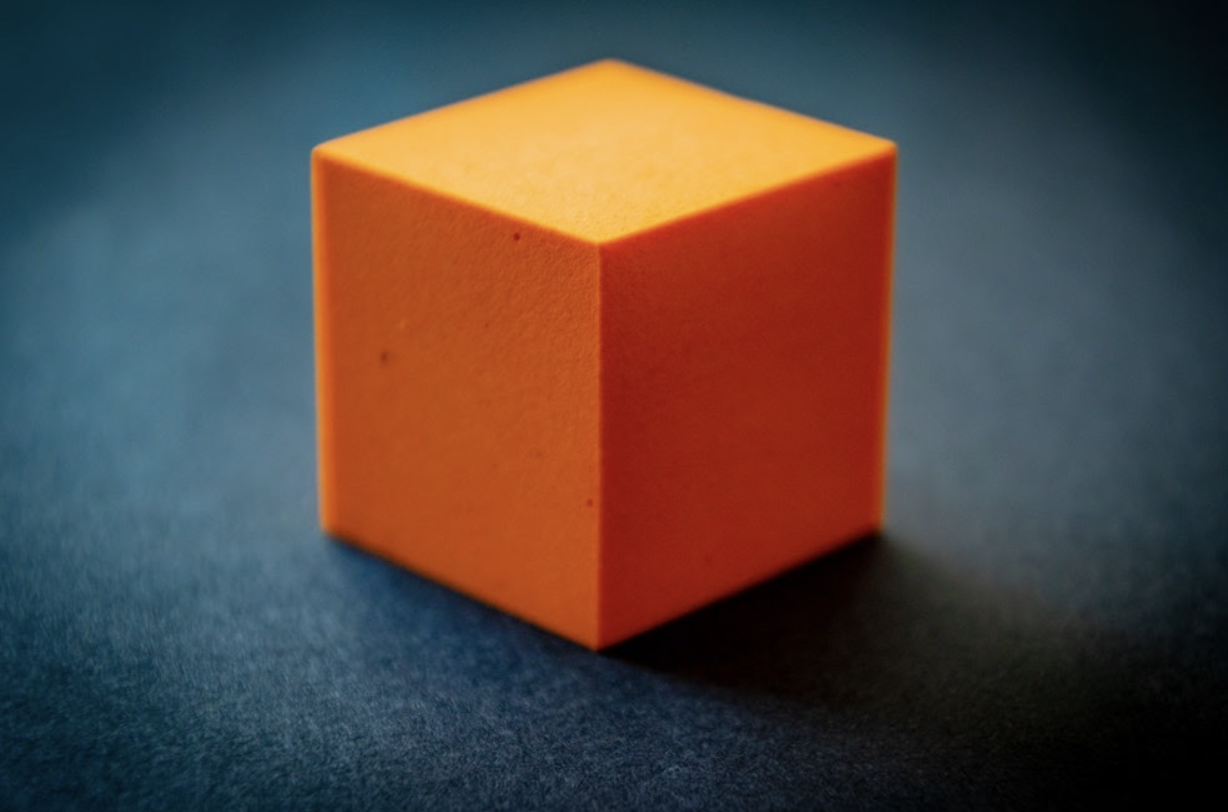

What Is Closed Cell Foam?

In the foam-manufacturing process, chemicals are combined and then heat is introduced. This causes a thermal reaction, and the compound expands. Closed cells fill up with gas or air and stay intact. They do not rupture or connect with other cells.

There’s a secondary level of closed cell foam called semi-closed cell foam (or crushed foam). It’s created when closed cell foam is crushed just enough to rupture a small number of cells.

Closed cells make foam harder or firmer, which means it has less flexibility, but more strength. This type of foam has a higher compression set. It will not retain its original shape when flattened for long periods or with heavy items.

Closed cell foam will not settle or shrink. This foam has a high insulation value and will perform in hot weather as well as cold temperatures. It also has strong dust resistance.

One of the best features of closed cell foam is its water resistance. It helps protect against mold and mildew because it inhibits moisture-driven elements. The smaller and more compact the cells are, the more water-resistant the foam will be.

What Are the Best Uses for Closed Cell Foam?

The purpose of closed cell foam is to block sound, keep out water, absorb energy, and add strength.

If you have a noisy furnace, you could insulate it with closed cell foam and muffle the sound. Or if you’re starting a band in the garage, but don’t want to bother the neighbors, you can dampen the sound that escapes the area with this type of foam.

When you need to keep both air and water out of a product, closed cell foam does the trick. It’s used in outdoor electrical panels and any type of gasket work where you need a watertight seal.

Closed cell foam is great for energy absorption. It’s used in cell phones, helmets, and other products that can take hits. Closed cell foam plays a big role in the packaging, automotive, and medical industries.

While open cell foam is thermoset, meaning it cannot be broken down again by heat, closed cell foam can be either thermoset or thermoplastic. This means closed cell foam can be remolded and reshaped while maintaining its strength.

When Should I Avoid Using Closed Cell Foam?

You don’t want to use closed cell foam in your product if you want to absorb sound, keep out air only, or have some flexibility.

Closed cell foam should not be used when you want to improve the acoustics of a space (such as a recording studio). The sound would bounce off the walls, cause reverberations, and affect the final product.

While closed cell foam does prevent both air and water from seeping in, it’s not cost-effective if you only need an airtight seal. Open cell foam does the same job at a more affordable price.

If you’re looking for your product to retain its shape after compression, closed cell foam is not the way to go. An item like a sofa cushion would have a lasting imprint after several sittings.

In the end, if you’re looking for sound absorption, an airtight seal, or something that keeps its original form, you’re better off choosing open cell foam over closed cell foam. Crushed foam is another hybrid option for when you need a formable material that also has some resistance.

Why You Should Use Closed Cell Foam

Now you know what closed cell foam is, its best applications, and when you should use a different material.

Closed cell foam is good for:

- Sound dampening

- Watertight seals

- Shock absorption

- Thermoplasticity

Closed cell foam is NOT ideal for:

- Sound absorption

- Water absorption

- Airtight seals only

- Flexibility

Learning all the details you can about closed cell foam will help you decide whether it’s the best fit for your project. If it’s not, you have other options to choose from, such as open cell foam or crushed foam, to reach your desired outcome.