Medical devices are often complicated and full of moving parts. These components usually generate heat, which can have a negative effect on products if the temperature gets too high.

Luckily, there are multiple materials equipped to deal with this potential threat. Whether they serve to block heat entirely or merely disperse it, there are certain products with the necessary qualities to keep whatever medical products you create safe for all to use.

In this guide, the material experts at Mueller are going to break down what applications require heat-resistant materials, what those materials are, and how to decide between them. With this information, you’ll be able to create the safest health and safety devices possible.

What Medical Applications Require High-Temperature Resistant Materials?

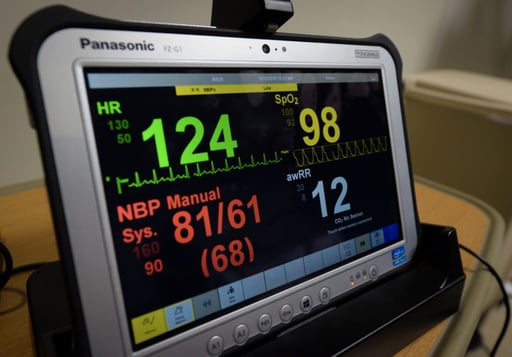

Heat and high temperature resistance is most necessary in electronic medical devices with components that generate heat. This includes products that have:

- Sensors

- Chips

- Valves

- Moving parts

- Motors

These components can be found in medical products such as breathing assistance devices and heartbeat monitors, as well as other sensors or analytical equipment.

Many of these products also require materials that are UL flame retardancy-rated. It is especially important that medical devices have flame-resistant properties. Since these products are used to either assist or save lives, it is crucial that they are as secure as possible.

What Materials Used in the Medical Industry Have High Heat Resistance?

There are almost countless materials that have some degree of heat resistance, but only a few that are commonly used in the applications discussed above. Some of these commonly used materials include:

- Silicone (foam, rubber, sponge)

- Fluorosilicone (foam or rubber)

- Teflon film

- Mylar film

Fluorosilicone foams and rubbers offer a high temperature-resistance range, with regular silicone closely behind. However, these materials cannot be used in applications where a thin material is necessary. In those applications, you need a film of some sort. You can use mylar, teflon, or even adhesives with silicone coatings.

These materials all have shielding properties and are designed to keep the heat away from the outer edge of a product, where a user might handle it. While some can disperse heat, most function to simply block heat from escaping and affecting other aspects of the device.

How Do You Decide Which Material to Use?

While many electronic medical devices do not have excessive heat requirements, you want to select a material that ensures a consistent and safe experience for users. Even if components only ever heat up to 250 degrees, it’s important to make sure your device is prepared.

Your first decision point is related to the required density of a material. If your product requires a thick barrier, you want to use a silicone or fluorosilicone rubber. If you need your material to be flexible or take on a compression set, then use a foam.

For thinner applications where you use a tape or film, you should decide based on what kind of adhesive is on it. Silicone-based adhesives are rated higher for heat than acrylic-based ones.

Generally, the customer will detail how thick or thin that the material needs to be, as well as providing a temperature range that the device will operate in. They should also describe what the application is and what the product does to further inform your decision.

The information provided to you should also include whether or not the materials need to be flame-rated. Most medical applications do, but it’s important to check.

We suggest trying to get as much information on the product and its application in order to recommend the right material to your clients. Collecting important details before selecting a material will help keep your process running smoothly.

Why Is Selecting the Right High-Temperature Material So Important?

More than many other industries, it is crucial for medical devices to be as safe as possible for users. The products you create help people live and maintain a high quality of life, making it essential for them to be as comfortable as possible as well.

If your products generate heat, then you need to pick the right material to block and dissipate these high temperatures to prevent discomfort or malfunctions. By understanding the different materials that do this, as well as their defining qualities and applications, you can create better, safer products for your customers.