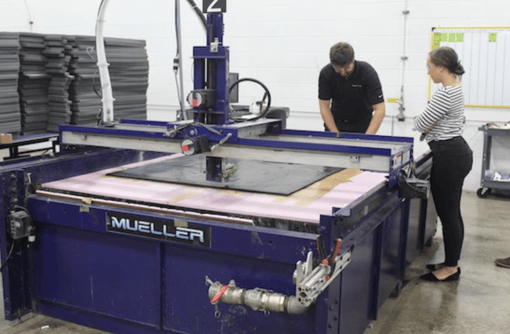

When you work with Mueller Custom Cut, you get a personalized experience.

Read the full article hereMueller Blog

When you work with Mueller Custom Cut, you get a personalized experience.

Read the full article here

When you work with Mueller Custom Cut, you get a personalized experience.

Read the full article here

You may be familiar with how Mueller Custom Cut proposes quotes to our customers.

Read the full article here

One of Mueller Custom Cut’s best services is showing our customers alternate materials for their applications.

Read the full article here

To solve a problem, sometimes you have to work with what you have because you don’t know another solution exists.

Read the full article here

When the pandemic and recession hit in early 2020, businesses began looking for new opportunities.

Read the full article here

When it comes to tapes and adhesives, an off-the-shelf solution may not be the best fit for your company.

Read the full article here

At Mueller Custom Cut, our ability to create innovative solutions for our customers is enhanced by our business partnership with 3M.

Read the full article here

When you come to Mueller Custom Cut with a new design for a product, we want to know everything about it.

Read the full article here

When you need an innovative custom cut solution, you should work with a company that can deliver what you want.

Read the full article here

“Begin with the end in mind.”

Read the full article here

Mueller Custom Cut is heading into 2021 on a high note.

Read the full article here

When choosing a material for your project, you need to know two things:

Read the full article here

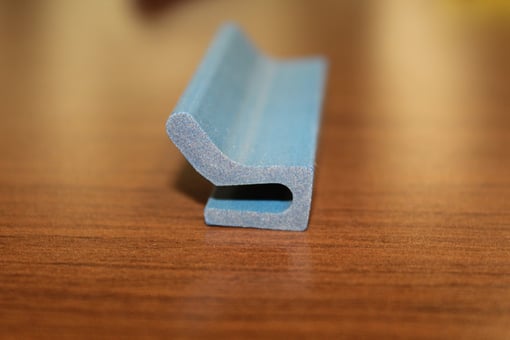

If you’ve thought about using closed cell foam for your next project, you should learn everything you can about the material, so you can make the best decision.

Read the full article here

Efficiency is everything.

Read the full article here

Even before the pandemic became a serious matter back in the spring, Mueller Custom Cut hit the ground running and never looked back.

Read the full article here

By now, it’s clear COVID-19 isn’t going away anytime soon.

After months of staying home and trying to flatten the curve, it’s time for students to get back into the classroom and companies to bring back workers to do business.

At Mueller, we are closely following the recommendations of the CDC to ensure we are doing everything in our power to provide a hygienic and safe work environment for our employees.

Read the full article here

As schools and businesses work to get their students and employees back inside buildings, there’s growing concern these facilities may have to close again if there are new outbreaks of the coronavirus.

There’s good reason to worry. We’ve already seen it happen.

Read the full article here

When you’re stuck trying to come up with an answer to a problem, sometimes it’s best to walk away and let it come to you. Other times, you need to go in search of the solution—and get a second opinion.

Read the full article here

Going back to school has never been so complicated.

As leaders continue to make decisions about sending students and teachers into classrooms again, they are considering a wide range of precautions in the hopes of preventing the spread of disease.

Read the full article here

There’s always a better way.

A better way to handle conflict.

A better way to manage your time.

A better way to use your market development funds.

Market development funds (MDF) are often overlooked. They tend to be used at the end of the year for branding on items like golf balls, t-shirts, and hats.

Read the full article here

Ready? Set? Pivot!

Once the reality of the COVID-19 outbreak set in, governments, businesses, and schools were forced to find new directions. However, no one really had an “in case of pandemic, break glass” box in their office.

Read the full article here

“We’re all in this together.”

Influencers and commentators utter these words repeatedly on TV and online as we try to figure out how to live in a world with COVID-19. Though it’s beginning to sound like a broken record, the sentiment is one Mueller takes seriously.

Read the full article here

We’ve learned a lot from the COVID-19 outbreak so far.

Our need for face-to-face interaction with family and friends is substantial. The number of times we touch our faces every day is absurd. How much we rely on imported materials is frightening.

The global pandemic has put a serious strain on our economy and disrupted the way we do business. It’s vital to support U.S. companies now more than ever.

Read the full article here

As lives are lost, routines are disrupted, and priorities are shifted, we at Mueller have found ourselves in a unique position to pitch in during this turbulent time.

We want to contribute to the effort to help first responders shield themselves in their dauntless attempts to treat patients. We also know you want to do your part in providing for medical professionals who are in dire need of personal protective equipment (PPE).

Read the full article here

People are in need of face shields more than ever. That’s why we’re ramping up our production of PRO-SHIELD 1 here at Mueller.

We’ll explain what a face shield is (they are not the same as surgical face masks and respirators), Mueller’s experience creating them, and an introduction to the face shield we’re creating to help those in need.

Read the full article here

Material testing and qualification is very important in all industries, especially health and safety. Making sure your materials have the proper certifications is essential for creating great products, so it pays to confirm that you meet those requirements.

Read the full article here

The health and safety industry holds its tools and devices to a very high standard, and rightfully so. These products are used in and around people who need them, making it very important to ensure that they are safe.

Read the full article here

The medical industry is highly regulated, with little room for error or unsatisfactory products. That’s why it’s important to know what you need from your materials before you go into production, including the numerous factors that contribute to selection: tests, certifications, and other processes.

In this guide, the health and safety experts at Mueller will explain the factors and questions that should guide your material selection and inventorying processes. We’ve listed the different sections below, so feel free to select the topic most pertinent to your business before moving on to others.

Read the full article here

In the medical world, clean and sterile equipment is very important. As businesses that operate in this industry, we often have to produce parts that users can sterilize. How do you know what sterilization process is correct? And what materials can even be sterilized?

Read the full article here

Your business works hard on your products, carefully planning and testing before sending them off to customers. However, mistakes can happen, and they often have serious consequences.

Read the full article here

Manufacturers across the globe are constantly creating new, innovative products in markets like health and safety. To keep your business competitive, you need a process that gets results quickly. Rapid prototyping does just that.

Read the full article here

Products used in hospitals, dentist offices, and medical practices often save lives, and everything from IV bags to MRI machines relies on reliable materials. As a result, you wouldn’t be blamed for thinking that those materials cost more than those in, say, the HVAC industry.

Read the full article here

Medical devices are often complicated and full of moving parts. These components usually generate heat, which can have a negative effect on products if the temperature gets too high.

Read the full article here

Recently, there has been a movement in the manufacturing world to decrease inventory overhead. Without realizing it, your business might be overspending on inventory management and stocking.

Read the full article here

When you think of conditioned air, you probably imagine walking into a cool room on a hot day. With the help of air handlers, we have found ways to control the temperature and keep both our living and working spaces comfortable.

Read the full article here

The pipes that connect a unit are vital when it comes to HVAC applications. In order to keep a product up and running, pipes must remain free of moisture or stress, which is where insulation tubing comes in.

Read the full article here

There are numerous environmental factors that can affect the performance of a product, but fire might be the most destructive. To counteract this force, manufacturers developed flame-resistant materials and chemicals to protect our products.

Read the full article here

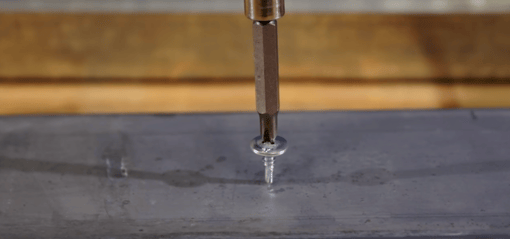

That’s where adhesives come in. Adhesives make an excellent case for replacing mechanical fasteners in many applications: they perform multiple functions at the same time, can decrease assembly time, and create more aesthetically pleasing products. But how do you know if adhesives are the right substitution for your project?

Read the full article here

The HVAC market has been around for some time, which means that certain materials are recognized as the best of the best. Among the most common materials are fiberglass and foams, including crushed, open-cell, and closed-cell varieties.

Read the full article here

Transportation is a massive and ever-changing industry, with countless opportunities for profit. However, you can only do this by creating products of the highest quality. Quality starts with materials, which means you have to make the right choices when it comes to parts.

Read the full article here

There’s nothing worse than a noisy product. Some items, like generators or air conditioning units, are noisy by nature. However, when something begins buzzing, squeaking, or rattling, there might be more considerable problems.

Read the full article here

When you manufacture a product, you want it to be durable and work efficiently. However, factors like heat and noise can affect your product negatively.

When you manufacture products across different industries, it’s important to find materials that meet multiple needs. If your business is in this situation, chances are you’ve heard of PVC foam.

Read the full article here

It is crucial for automotive manufacturers to be aware of all potential issues with the vehicles they produce. These issues all start with the materials that make up a product, which makes choosing the right one is key.

Read the full article here

Most products that your business produces will require adhesives to help them function properly, which is why choosing the best tape or adhesive for your products every time is so important. If you don’t make the right choice, your products increase their risk for failure.

Read the full article here

When you begin the process of sourcing a custom cut solution, you naturally want the lowest price possible. However, it is difficult to learn how you can get that low price without first understanding the costs and fees associated with your solution.

Read the full article here

The automotive industry is rapidly changing. One of the most significant changes recently is the focus on reducing the output of pollution originating from materials used while manufacturing vehicles.

Read the full article here

Great products start with great materials, making sourcing an important step in any supply chain.

As procurement officers, choosing the right material source for both you and your customers can be a difficult decision. Should you source materials domestically? Or should you look offshore for materials? Does the source even matter?

Read the full article here

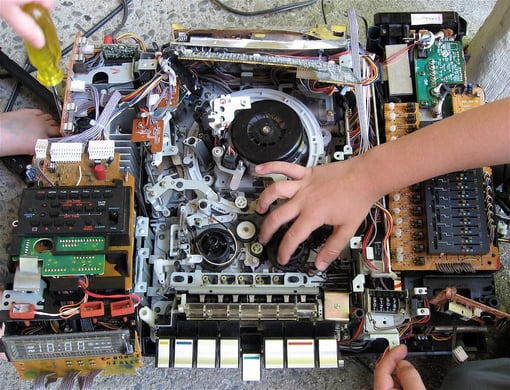

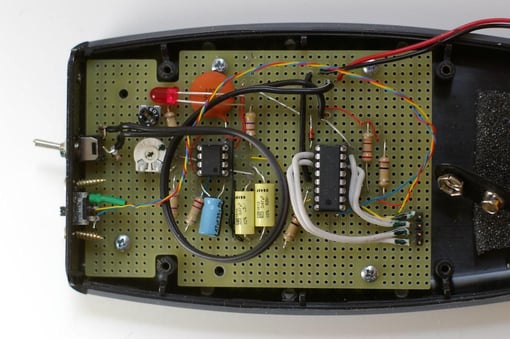

Electronics are likely a massive source of business for your company. With that in mind, you must be confident that the products you’re producing are built to last and get the job done. At Mueller, we’re here to make sure that your electronics do just that.

Read the full article here

When it comes to electronic products, consistent performance is vital. However, when electromagnetic interference (EMI) comes into play, performance can be jeopardized. Luckily, there are ways to ensure the integrity of a product.

Read the full article here

There are plenty of issues that can be planned for when developing electronic products. Many times, you can account for factors like noise, temperature, and insulation. However, one of the most essential elements to consider is the environment the product will be in.

Read the full article here

As long as machines, tools, and devices have running parts, they will have heat, and as we all know, too much heat can be problematic. With heat dissipation materials, those issues can be avoided in electronic products. However, it isn’t always clear what material to use to dissipate heat in your products best.

Read the full article here

As consumers, we know there’s nothing worse than a noisy product. But as manufacturers, we also understand that ensuring our product’s functionality is the number one priority during production.

Read the full article here

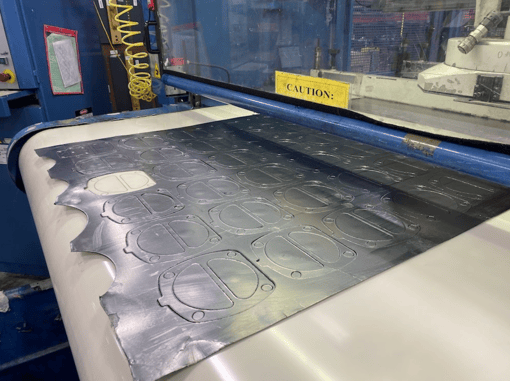

When looking for the perfect way to seal your next product, the variety of potential gaskets on the market can be overwhelming. Chances are you’ve determined you need a gasket, but may not be sure of the material you need to use.

Read the full article here

As a consumer, it is natural to wonder how the price of any product or service is determined. Plenty of companies will give you a quote, but how many actually explain what determines the cost that a quote provides?

Read the full article here

When choosing the proper adhesive for your part it is imperative to know the application. Will the part be wrapping around an object? Will the parts be laying flat? Is there an extreme bend (90°, 180°, etc.)? These are the types of questions that when answered up front can determine whether your part will perform to expectations or fail once placed on the production parts.

Read the full article here

Attention to detail is crucial when crafting electronic products. That’s why it’s crucial to select the correct type of gasket for your product, which isn’t always an easy decision to make.

Read the full article here

Supply Chain Reaction - Auto Gaskets

DOWNLOAD HERE >

A Value-Add Proposition - HVAC Gaskets

DOWNLOAD HERE >